|

Egmec Industry Co., Ltd.

|

High Working Pressure Grease Pump

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. For lubrication of low frequency

2. Port no. in the range 1 to 14 optional

3. High Pressure up to 31.5MPa

High Working Pressure 315bar/4567.5psi Grease Lubrication Pump

The DB-N Series of High Working Pressure 315bar/4567.5psi Grease Lubrication Pump is low frequency used for lubrication, lubrication points 50 points below the single-wire nominal pressure 31.5MPa small machinery lubrication system, single distributor, directly or through delivery to all grease lubrication points for the delivery of oil installations. The pump is used in metallurgy, mining, port, transport, construction and other equipment.

The DB-N Series of High Working Pressure 315bar/4567.5psi Grease Lubrication Pump is low frequency used for lubrication, lubrication points 50 points below the single-wire nominal pressure 31.5MPa small machinery lubrication system, single distributor, directly or through delivery to all grease lubrication points for the delivery of oil installations. The pump is used in metallurgy, mining, port, transport, construction and other equipment.

How to use High Working Pressure 315bar/4567.5psi Grease Lubrication Pump:

The High Working Pressure 315bar/4567.5psi Grease Lubrication Pump should be installed in the interior, less dust, vibration small, dry place, with a bolt fixed to the foundation. Operating space left around it. Location should be easy to install grease supply, commissioning, inspection, maintenance and so easy to remove and the occasion, which is required before using the reducer piston into the oil chamber (Recommended industrial gear oil N220), the red line to the location of the oil level gauge.

Most of the new lubrication pump oil should be replaced after 200 hours, after every 2,000 hours of new oil changed regularly, and should always check the oil, and if the oil quality deterioration, it should shorten the replacement cycle. Filling the grease inside the oil storage must be used pumps from the grease supply port to join. Grease used should be clean, does not allow impurities, dirt, dust, air bubble exists.

Electric lubrication pump with the arrow indicating the direction of rotation direction, should be aware of this.

Set pressure relief valve as standard 42MPa.

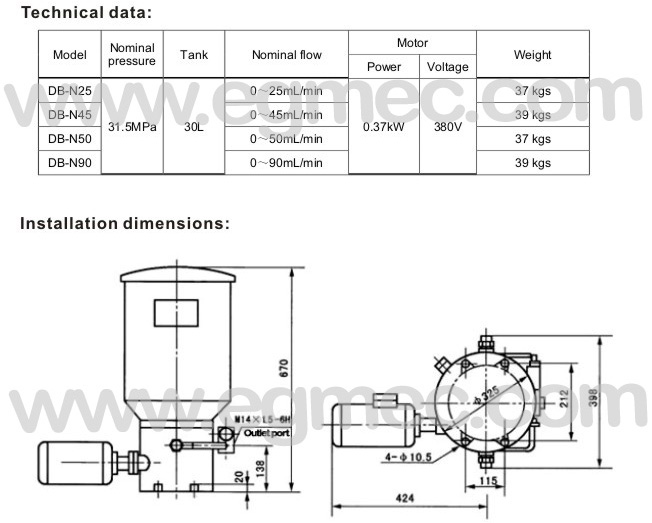

High Working Pressure 315bar/4567.5psi Grease Lubrication Pump technical data and installation dimensions as follow;

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

High Pressure Pump

High Pressure Water Pump

Grease Pump

Air Grease Pump

Air Operated Grease Pump

Pneumatic Grease Pump

More>>

.jpg)

.jpg)