|

Egmec Industry Co., Ltd.

|

Lubrication Progressive Grease Distributor

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Easy operation and maintenance

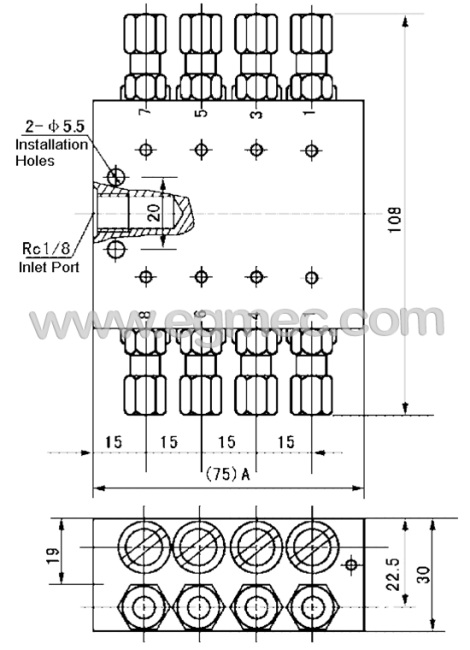

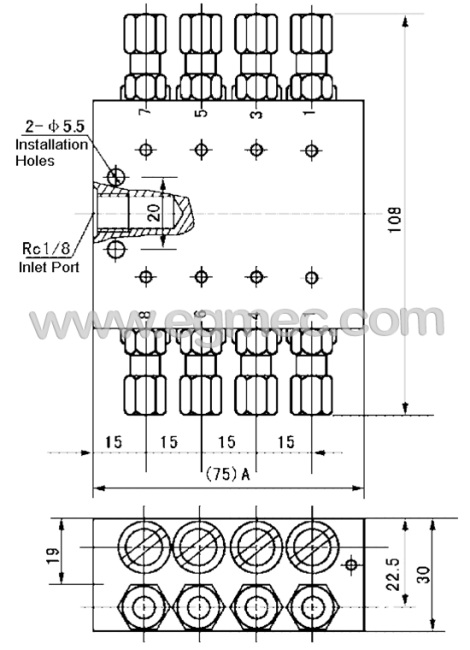

2. With 5.5mm size installation holes

3. Injectors are equipped with the blocks

Brief introduction:

The SSV14 series progressive grease distributor is available for the lubrication equipment with operation pressure of 4350Psi. The SSV series have the characteristics of easy maintenance, please check the following steps to fix fault element and extend the distributor service life:

1. Loosen the bottom of the grease port corresponding screw plug, reciprocating push the piston ( be careful not to slip out ), to screw the plug back if the piston moves smooth in the grease flow passage, then checking other distributor block one by one.

2. Removing the piston if there is problem of movement in the flow passage, check the distributor hole and surface scratches, it is needed to be replaced the element pieces if there is such as severely scratched ( Note: each piston are not interchangeable).

3. It indicates that the distributor needs to be clean completely if the surface of the piston and the inner bore with the traces of hard dry grease. To increase the pressure to 2900Psi by manually grease gun and immersed the distributor in 90 ° C hot water, clean the remains grease until the pressure dropped to 0Psi, please note that the corresponding pipeline should be thoroughly cleaned.

4. Detect and clean all the distributor elements, installed the elements as the standard , pay attention to seals correct installation position, does not allow defect or prominent, check the first element of the seal between the middle of the elements and the last element. To avoid piston blocked, tighten the mounting bolts should be specified torque.

5. Final step is to feed the distributor with grease by grease injection gun, install the distributor in the lubrication systems if it is normal working, then start checking the entire system.

The block distributor failure detection can refer to a sheet distributor, however, note that, the block allocator can not continue to use once a piston or the surface of the inner bore is severely scratched.

Specification:

The SSV14 series of modular lubrication progressive grease distributor faults and troubleshooting:

First check whether the lubrication pump is operation and lubricant to the main distributor if any device or any turned bearing is blocked, then open the allocator inlet connector lubricant overflow prove distributor is the root cause of the failure.

Connected to the inlet connector tightening, followed by open belongs bearing oil inlet connector lubricant overflow, which indicates the bearing is blocked. When the inner blocked in the distributor, it should replace with the new distributor case of emergency can be cleared under the following conditions.

The SSV14 series progressive grease distributor is available for the lubrication equipment with operation pressure of 4350Psi. The SSV series have the characteristics of easy maintenance, please check the following steps to fix fault element and extend the distributor service life:

1. Loosen the bottom of the grease port corresponding screw plug, reciprocating push the piston ( be careful not to slip out ), to screw the plug back if the piston moves smooth in the grease flow passage, then checking other distributor block one by one.

2. Removing the piston if there is problem of movement in the flow passage, check the distributor hole and surface scratches, it is needed to be replaced the element pieces if there is such as severely scratched ( Note: each piston are not interchangeable).

3. It indicates that the distributor needs to be clean completely if the surface of the piston and the inner bore with the traces of hard dry grease. To increase the pressure to 2900Psi by manually grease gun and immersed the distributor in 90 ° C hot water, clean the remains grease until the pressure dropped to 0Psi, please note that the corresponding pipeline should be thoroughly cleaned.

4. Detect and clean all the distributor elements, installed the elements as the standard , pay attention to seals correct installation position, does not allow defect or prominent, check the first element of the seal between the middle of the elements and the last element. To avoid piston blocked, tighten the mounting bolts should be specified torque.

5. Final step is to feed the distributor with grease by grease injection gun, install the distributor in the lubrication systems if it is normal working, then start checking the entire system.

The block distributor failure detection can refer to a sheet distributor, however, note that, the block allocator can not continue to use once a piston or the surface of the inner bore is severely scratched.

Specification:

Model | Nominal pressure | Oil feeding flow | Starting pressure | Outlet port | Weight |

SSV-14 | 30Mpa | 0.2 ml/Cycle | ≤1.5Mpa | 14 | 3.0kgs |

Note: Using the medium for the cone is greater than 265 (25 ℃, 150g) 1/10mm, (NLGI0 # -2 #) of the grease. Such as the use of oil, viscosity grade than N68.

Code explanation:

SSV–14–K

SSV= SSV series of progressive divider valve

14= Numbers of outlets, 14 outlet ports

K= With indicator; Without indicator if omit

SSV14 series of dimensions:

Model | A | Max. Medium Flow Rate(ml/min) |

SSV-14 | 120 | 900 |

1.Outlet injectors : φ6 (Installed with the blocks)

2. Maximum pressure loss 10-20bar when grease through the working cell at25 ℃ temperature.

2. Maximum pressure loss 10-20bar when grease through the working cell at25 ℃ temperature.

The SSV14 series of modular lubrication progressive grease distributor faults and troubleshooting:

First check whether the lubrication pump is operation and lubricant to the main distributor if any device or any turned bearing is blocked, then open the allocator inlet connector lubricant overflow prove distributor is the root cause of the failure.

Connected to the inlet connector tightening, followed by open belongs bearing oil inlet connector lubricant overflow, which indicates the bearing is blocked. When the inner blocked in the distributor, it should replace with the new distributor case of emergency can be cleared under the following conditions.

1. The workplace should be clean.

2. Remove the inlet and outlet connectors.

3. Remove the screw plug of the piston bore two sides.

4. To push the piston out with a soft rod ( Diameter less than 6mm, as far as possible the plastic rod ).

5. Cleaning of the distributor body with the compressed air blowing and.

6. Checking the distributor body flow passage holes with the fine wire ( F1.5mm ).

7. Cleaning and blowing distributor body again.

8. To replace the copper washers, reassemble the distributor.

9. Checking the new assembled distributor with a manual pump, then the distributor starting pressure can not be higher than 25bar. If the starting pressure is higher than 25bar, the distributor should be replaced.

2. Remove the inlet and outlet connectors.

3. Remove the screw plug of the piston bore two sides.

4. To push the piston out with a soft rod ( Diameter less than 6mm, as far as possible the plastic rod ).

5. Cleaning of the distributor body with the compressed air blowing and.

6. Checking the distributor body flow passage holes with the fine wire ( F1.5mm ).

7. Cleaning and blowing distributor body again.

8. To replace the copper washers, reassemble the distributor.

9. Checking the new assembled distributor with a manual pump, then the distributor starting pressure can not be higher than 25bar. If the starting pressure is higher than 25bar, the distributor should be replaced.

Modular lubrication progressive grease distributor

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Distributor

Lubrication

Distributor Cap

Distributor Rotor

Progressive Die

Ignition Distributor

More>>

.jpg)

.jpg)