|

Egmec Industry Co., Ltd.

|

Modular Lubrication Progressive Blocks

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Low starting operation pressure

2. Reliable working characteristics

3. Model of 6 to16 series option

Brief introduction:

The SSV12 series modular lubrication progressive distributor block IS available for the lubrication equipment of operation pressure with 300bar.To keep the distributor in a long term service, it must ensure the quality of the grease / oil , the / oil to be used in strict accordance with the requirements of the system.

The engagement between the piston and the grease chamber in the distributor is more precise, the clearance fit tolerance is generally 3 μm. If poor quality grease is used, grease gap lubrication cycle (30 ~ 40 bar) under high pressure segregation phenomenon, namely crude oil from the soap separation, if the time is long enough , as more than seven days , the soap will solidified in the piston guide ring groove and the grease / oil chamber , which leads to the distributor in a blocked state even under the pressure of 300bar.

Note: Using the medium for the cone is greater than 265 (25 ℃, 150g) 1/10mm, (NLGI0 # -2 #) of the grease. Such as the use of oil, viscosity grade than N68.

Code explanation:

SSV–12–K

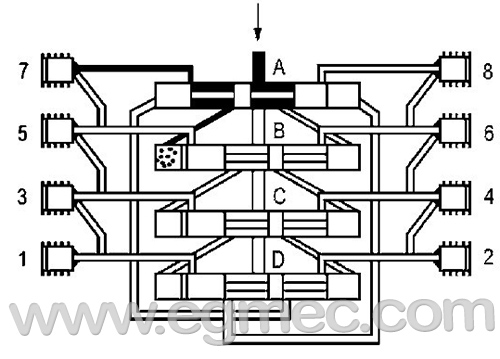

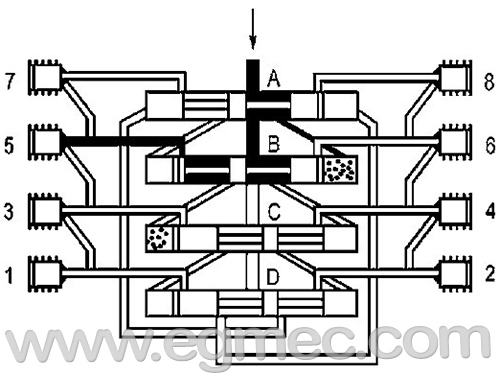

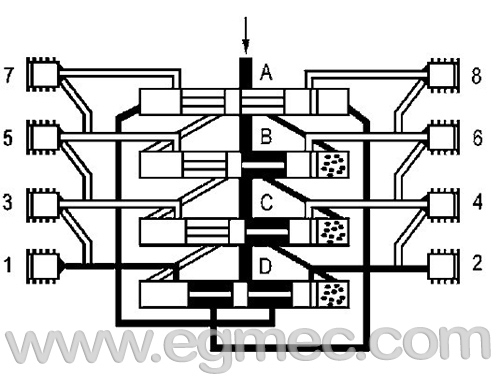

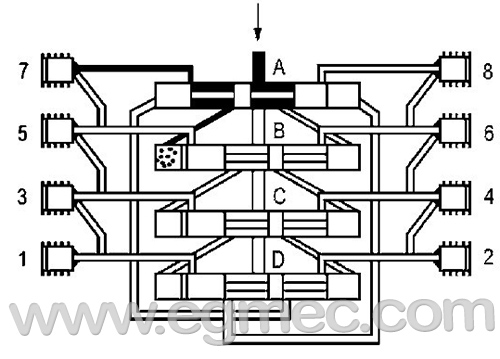

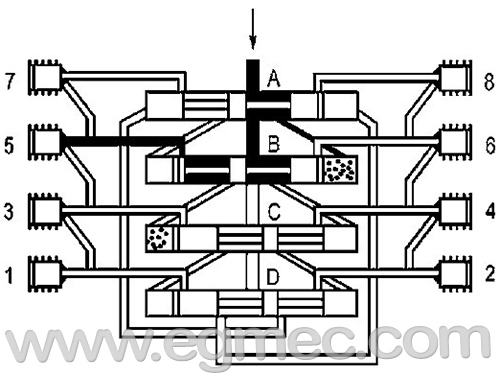

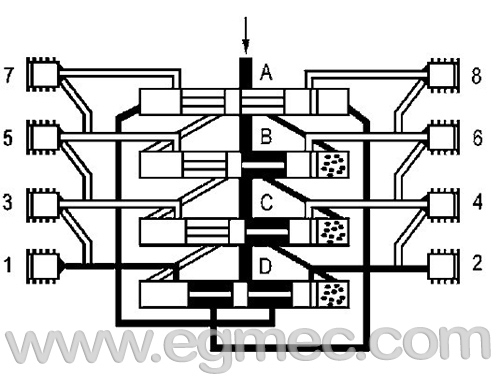

Model SSV12 series of progressive distributor blocks description:

The grease/ oil enters into the distributor as per the direction of the arrow marked on the drawing above and transports to the end right of the piston A. The piston A moves to the left by the grease/oil pressure. The grease/oil in the position of piston A front left is transported to outlet 2 through internal passage of the house, reaches and lubricates the friction parts.

The right end passage connection of piston B is open while the piston A reaches the position of left end. The grease/oil flows into the right position of piston B and pushes the piston B moving to the left. The grease/oil store in left front of piston B is delivered to the outlet 7 through internal passage of the house.

The right end passage connection of piston C is open while the piston B reaches the position of left end. The grease/oil flows into the right position of piston C and pushes the piston C moving to the left. The grease/oil store in left front of piston C is delivered to the outlet 5 through internal passage of the house.

The right end passage connection of piston D is open while the piston D reaches the position of left end. The grease/oil flows into the right position of piston D and pushes the piston D moving to the left. The grease/oil store in left front of piston D is delivered to the outlet 3 through internal passage of the house.

The right end passage connection of piston D is open while the piston A reaches the position of left end. The grease/oil flows into the left position of piston A and pushes the piston A moving to the right. The grease/oil store in right of piston A is delivered to the outlet 1 through internal passage of the house.

When the piston B to D moves from the left to the right, according to the opposite direction above sequence of actions to complete a cycle and it will be restarting a new cycle.

1. Recommended maximum through two-level distribution of lubricants in the system.

2. Outlets ports 1 and 2 should be never closed.

3. Always use the original injectors and outlets connection pipes.

4. Dismantling exchange the nozzle parts from of each side of the upper or the lower outlets.

5. The nozzle must be removed if the outlets need to be blocked, merge the volume of grease (Changing to lower outlet port), the M10x1 is used to block the injectors as per the drawing below for example.

The SSV12 series modular lubrication progressive distributor block IS available for the lubrication equipment of operation pressure with 300bar.To keep the distributor in a long term service, it must ensure the quality of the grease / oil , the / oil to be used in strict accordance with the requirements of the system.

The engagement between the piston and the grease chamber in the distributor is more precise, the clearance fit tolerance is generally 3 μm. If poor quality grease is used, grease gap lubrication cycle (30 ~ 40 bar) under high pressure segregation phenomenon, namely crude oil from the soap separation, if the time is long enough , as more than seven days , the soap will solidified in the piston guide ring groove and the grease / oil chamber , which leads to the distributor in a blocked state even under the pressure of 300bar.

Specification:

Model | Nominal pressure | Oil feeding flow | Starting pressure | Outlet port | Weight |

SSV-12 | 30Mpa | 0.2 ml/Cycle | ≤1.5Mpa | 12 | 2.5kgs |

Note: Using the medium for the cone is greater than 265 (25 ℃, 150g) 1/10mm, (NLGI0 # -2 #) of the grease. Such as the use of oil, viscosity grade than N68.

Code explanation:

SSV–12–K

SSV= SSV series of progressive distributor blocks

12= Numbers of outlets, 8 outlet ports

K= With indicator; Without indicator if omit

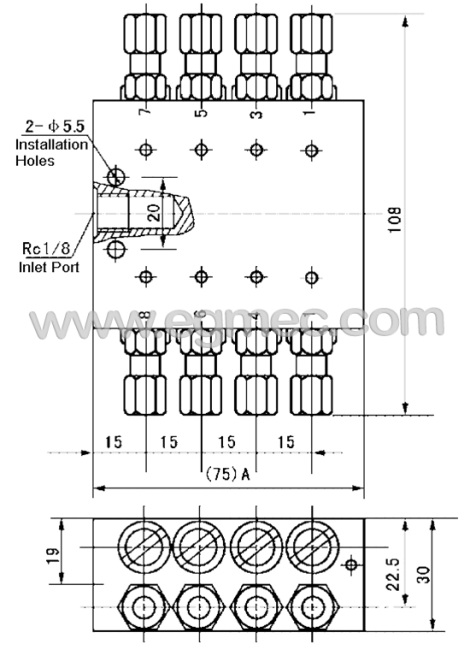

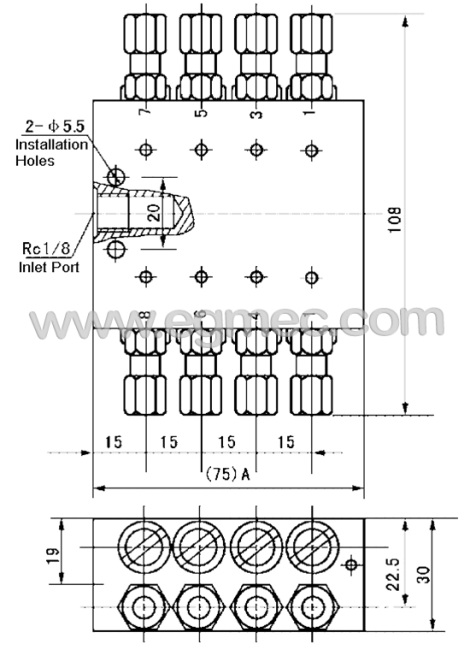

SSV12 series of modular lubrication progressive distributor block dimensions:

Model | A | Max. Medium Flow Rate(ml/min) |

SSV-12 | 105 | 800 |

1.Outlet injectors : φ6 (Installed with the blocks)

2. Maximum pressure loss 10-20bar when grease through the working cell at25℃ temperature.

2. Maximum pressure loss 10-20bar when grease through the working cell at25℃ temperature.

Model SSV12 series of progressive distributor blocks description:

The grease/ oil enters into the distributor as per the direction of the arrow marked on the drawing above and transports to the end right of the piston A. The piston A moves to the left by the grease/oil pressure. The grease/oil in the position of piston A front left is transported to outlet 2 through internal passage of the house, reaches and lubricates the friction parts.

The right end passage connection of piston B is open while the piston A reaches the position of left end. The grease/oil flows into the right position of piston B and pushes the piston B moving to the left. The grease/oil store in left front of piston B is delivered to the outlet 7 through internal passage of the house.

The right end passage connection of piston C is open while the piston B reaches the position of left end. The grease/oil flows into the right position of piston C and pushes the piston C moving to the left. The grease/oil store in left front of piston C is delivered to the outlet 5 through internal passage of the house.

The right end passage connection of piston D is open while the piston D reaches the position of left end. The grease/oil flows into the right position of piston D and pushes the piston D moving to the left. The grease/oil store in left front of piston D is delivered to the outlet 3 through internal passage of the house.

The right end passage connection of piston D is open while the piston A reaches the position of left end. The grease/oil flows into the left position of piston A and pushes the piston A moving to the right. The grease/oil store in right of piston A is delivered to the outlet 1 through internal passage of the house.

When the piston B to D moves from the left to the right, according to the opposite direction above sequence of actions to complete a cycle and it will be restarting a new cycle.

Modular lubrication progressive distributor block

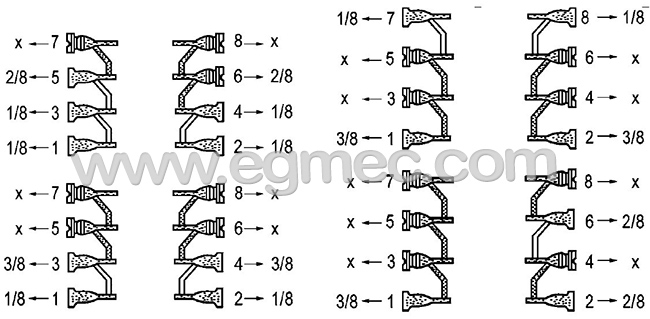

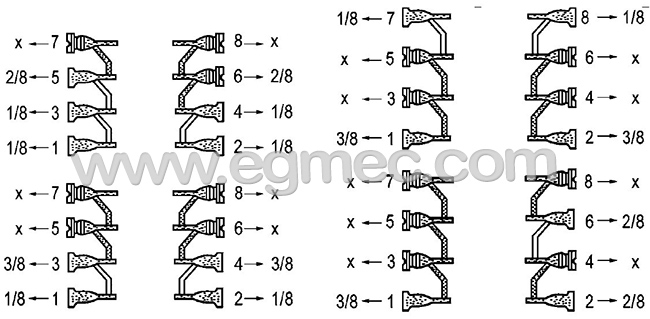

How to use SSV12 series of modular lubrication progressive distributor block:

1. Recommended maximum through two-level distribution of lubricants in the system.

2. Outlets ports 1 and 2 should be never closed.

3. Always use the original injectors and outlets connection pipes.

4. Dismantling exchange the nozzle parts from of each side of the upper or the lower outlets.

5. The nozzle must be removed if the outlets need to be blocked, merge the volume of grease (Changing to lower outlet port), the M10x1 is used to block the injectors as per the drawing below for example.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Lubrication

Progressive Die

Progressive Stamping

Lubrication System

Oil Lubrication

Lubrication Bearing

More>>

.jpg)

.jpg)