|

Egmec Industry Co., Ltd.

|

Lincoln Lubricant Distributors

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Replacement of ZP Series

2. Max. pressure operation: 160bar

3. Minimum start pressure: Less than or equal 10bar

Brief introduction:

In addition, if more than three, the number of intermediate piece according forth, any middle elements do not operate, other potion in the elements will all blocked, the entire distributor will stop working, this ingenious idea makes the monitor output oil is normal becomes extremely convenient, as long as the middle elements set proximity switch sensing the movement of the piston, the piston blocking timely alarm.

Ordering code:

6 JPQ 2 - K 0.2

Specification:

Note: Use the media to the Cone penetration is not less than 265 (25 ° C, 150g ) 1/10mm grease or lubricant viscosity grades than N68 . Applicable ambient temperature -20 ~ 80 ℃

JPQ1 Series and JPQ3 Series Oil Lubricant Distributor Type and Dimensions:

1. The distributor for the single- piston one element combination structure , each piece has two oil outlet , divided into JPQ1 , the JPQ2 , JPQ3 and JPQ4 of four forms.

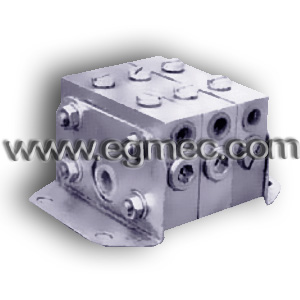

The JPQ-K series (Original Code of ZP type ) progressive Oil Lubricant Distributor for nominal pressure 16MPa single progressive dry oil lubrication system, grease quantitatively assigned to each lubrication point.

The progressive oil lubricant distributor mainly two types of chip and block, multi - chip distributor in the lubrication system, a progressive distributor by starting a piece, a termination of the chip and at least three intermediate slices, the number of the intermediate sheet can be theoretically N piece, but regardless of whether the number is the number, and the starting sheet and the termination piece combined into an integrated whole. The middle elements, each piece has a working piston and two output ports, the oil port located in the middle of the left and right ends of the sheet, as progressive distributor works.

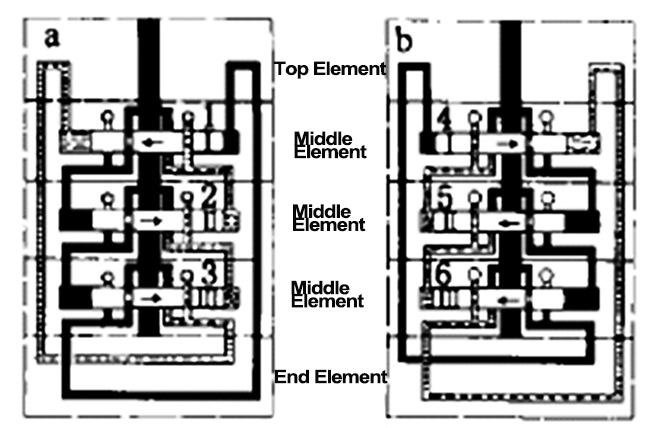

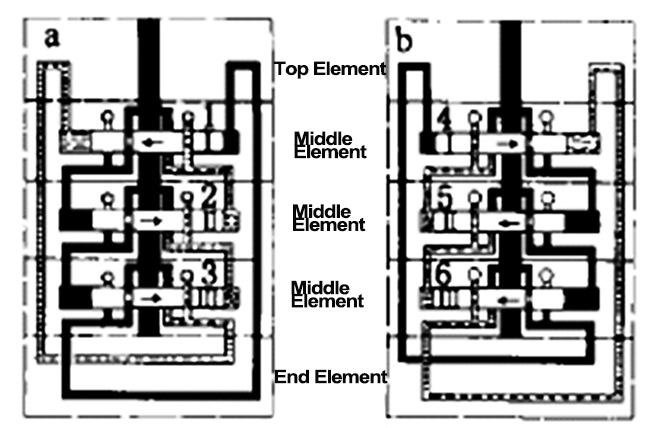

Please check the above drawing a, the lubricant elements from the inlet port of the upper portion into the annular groove reaches the left end of the piston II and the piston III and push them to move to the right, so that the lubricant in the cavity of the piston in sequence from the outlet port 1 and 2 discharge. When the piston reaches the right limit position III, into the lubricant dispenser by an annular groove on the left to reach the right end of the piston I is to promote the piston I is moved leftward, so that the lubricant is discharged from the output port 3 in the piston receiving cavity; while the process shown in drawing b is opposite in the direction of movement of the piston, and accordingly, the lubricant successively from the oil port 4, 5, 6 discharged. Lubricant to maintain a certain amount of pressure just go progressive distributor, the distributor will work continuously.

In addition, if more than three, the number of intermediate piece according forth, any middle elements do not operate, other potion in the elements will all blocked, the entire distributor will stop working, this ingenious idea makes the monitor output oil is normal becomes extremely convenient, as long as the middle elements set proximity switch sensing the movement of the piston, the piston blocking timely alarm.

Ordering code:

6 JPQ 2 - K 0.2

6= Numbers of outlets.

JPQ= Oil Lubricant Distributor Progressive Type

Combination type= JPQ1, JPQ2, JPQ3 and JPQ4 type

K= Nominal pressure: 160bar

Rated Grease feeding volume= 1.2mL/cycle (Please refer to technical specification)

Specification:

Model | Nominal pressure (bar) | Rated grease feeding volume of each outlet Ml/cycle | Start pressure (bar) | Middle elements (Pcs.) | Outlets (Pcs.) | |

Old Model | ||||||

JPQ1-K | ZP-A | 16 | 0.07 0.1 0.2 0.3 | ≤1 | 3-12 | 6-24 |

JPQ2-K | ZP-B | 0.5 1.2 2.0 | ||||

JPQ3-K | ZP-C | 0.07 0.1 0.2 0.3 | 4-8 | 6-14 | ||

JPQ4-K | ZP-D | 0.5 1.2 2.0 | ||||

Note: Use the media to the Cone penetration is not less than 265 (25 ° C, 150g ) 1/10mm grease or lubricant viscosity grades than N68 . Applicable ambient temperature -20 ~ 80 ℃

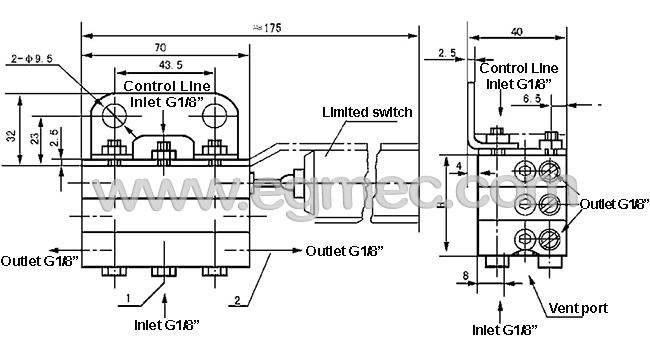

Oil Lubricant Distributor of JPQ Series Dimensions:

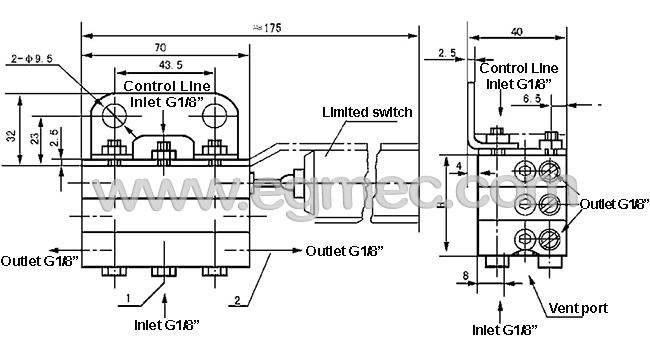

JPQ1 Series and JPQ3 Series Oil Lubricant Distributor Type and Dimensions:

Numbers of outlet | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

Elements (Pieces) | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

H (mm ) | 48 | 64 | 80 | 96 | 112 | 128 | 144 | 160 | 176 | 192 |

Weight (kg) | 0.91 | 1.2 | 1.5 | 1.7 | 2.0 | 2.3 | 2.5 | 2.8 | 3.1 | 3.3 |

JPQ2 Series Oil Lubricant Distributor Type and Dimensions:

Numbers of outlet | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

Elements (Pieces) | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

H (mm ) | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 |

Weight (kg) | 3.5 | 4.5 | 5.5 | 6.5 | 7.5 | 8.5 | 9.5 | 10.5 | 11.5 | 12.5 |

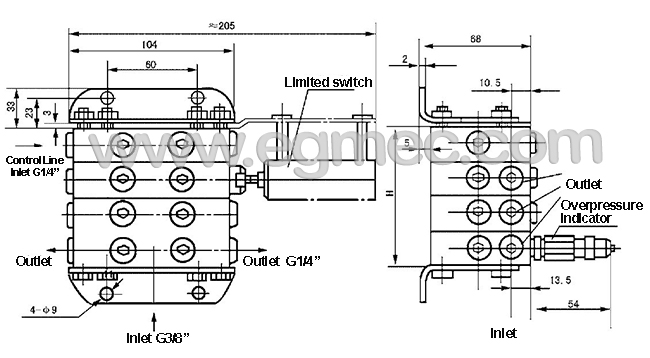

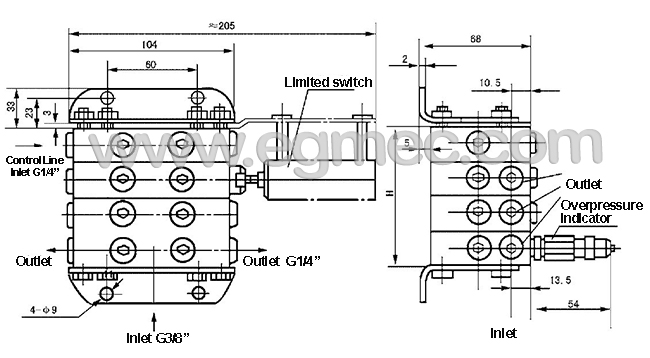

JPQ4 Series Oil Lubricant Distributor Type and Dimensions:

Numbers of outlet | 8 | 10 | 12 | 14 | 16 |

Elements (Pieces) | 4 | 5 | 6 | 7 | 8 |

H (mm ) | 100 | 125 | 150 | 175 | 200 |

Weight (kg) | 4.5 | 5.5 | 6.5 | 7.5 | 8.5 |

How to use JPQ of Oil Lubricant Distributor series:

1. The distributor for the single- piston one element combination structure , each piece has two oil outlet , divided into JPQ1 , the JPQ2 , JPQ3 and JPQ4 of four forms.

A. Each form of distributor, general rated to the amount of oil equivalent monolithic combination, the need also rated oil different monobrid combination.

B. JPQ4 combination of the need for a control element, this piece element oil to the port.

C. adjacent two or more oil to the port can be combined into an oil port to the oil , this all merged to ports rated to oil and oil to the oil port of.

2. The JPQ1 type and JPQ2 type distributor system used in series the JPQ3 - type and JPQ4 - type distributor is used in parallel in the lubrication system.

3. The lubricant distributor is equipped with a motion indicating rod, for the observation of the dispenser work. Limit switches can also be installed as required to control and monitor in the lubrication system.

4. The JPQ2 type , JPQ4 type lubricant distributor according to need can be installed overpressure indicator.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Lubricant

Lubricant Oil

Lubricant Oil Purifier

Lubricant Oil Pump

Lubricant Oil Filtration

Personal Lubricant Oil

More>>

.jpg)

.jpg)