|

Egmec Industry Co., Ltd.

|

High Pressure Portable Grease Pump

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Apply for high lubrication frequency

2. With cart to mobile lubrication equipment

3. Automatic control obtain if with electrical control box

Brief introduction:

The DRBZ-P Series of 40Mpa/5800psi High pressure Lubrication Portable Grease Pump are suitable for the high lubrication frequency, long length of the pipe and intensive lubrication points in single and two-lane grease centralized lubrication system, as a delivery device for the supply of grease.

Mobile lubrication equipment grease pump device can also be equipped with a mobile trolley, hose, oil gun and cable, suitable for the lubrication frequency is low, less lubrication points, not easy to adopt a centralized lubrication stand-alone device, move for grease lubrication.The 40Mpa/5800psi High pressure Lubrication Portable Grease Pump is the series for electric high-pressure piston type. Working pressure nominal pressure range can be adjusted, double overload protection. The grease reservoir level automatic alarm device will equipped with, lubrication pumps with electrical control box to achieve the two- centralized lubrication system automatic control and system monitoring.

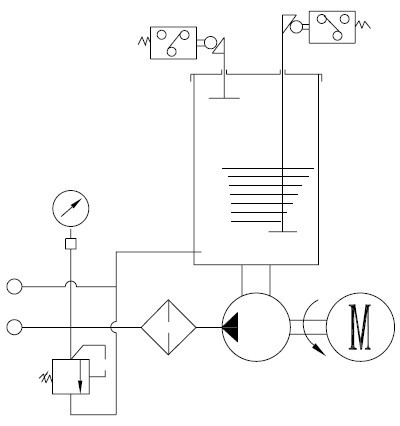

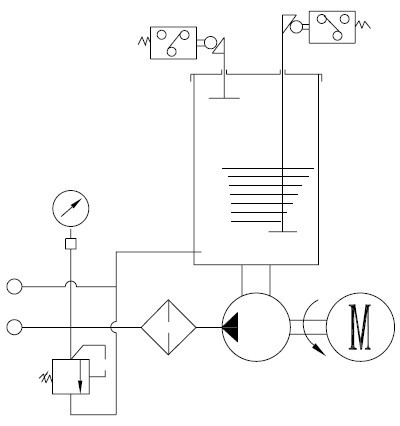

Function symbol:

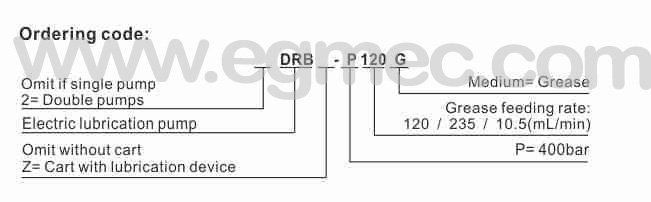

Ordering code:

Ordering code:

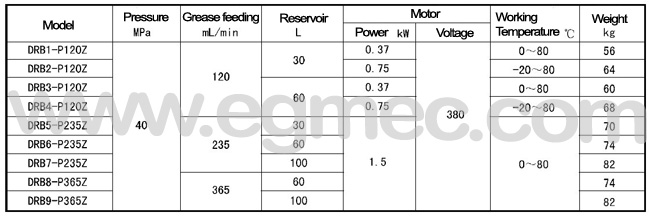

Technical information:

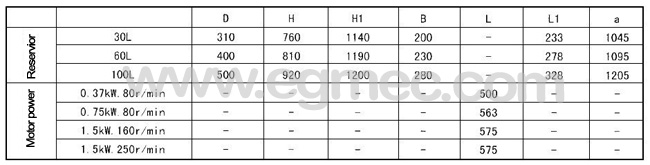

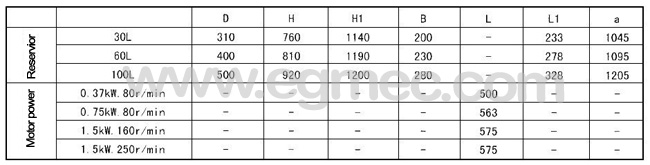

DRB-P 40Mpa/5800psi High pressure Lubrication Portable Grease Pump dimensions:

DRBZ-P 40Mpa/5800psi High pressure Lubrication Portable Grease Pump dimensions:

DRB-P lubrication equipment double grease pump dimensions:

DRB Series working principle:

Fixed gear motor flange connection with a pump device, driven by the eccentric shaft sliding fork for linear reciprocating motion, and driven spiral the pressure oil plate and oil scraper plate clockwise rotation (using the lubricant is no such institutions ), stir evenly softened grease is pressed onto the pump means around the suction port.

Pump body two groups of pistons, each piston is composed of a plug and the two control piston, when the pair of pistons in the operating piston to complete the oil absorption process, another set of pistons of the working piston put the grease pressure to the oil mouth.

As shown in the following figure, when the sliding fork moves to the left , on the set of the piston to complete suction, the group piston the complete pressure oil to start a new cycle.

Then the group pistons 1, 2 leftward movement of the piston 2 reaches the limit positions under the spring force to close the outlet, and the piston 1 continues leftward movement, when the piston 2 and a vacuum is formed between the degree of vacuum with the piston 1 left shift is increasing the sliding fork movement to the limit position of the piston to open the suction port, grease sucked from the suction port , such as the lack of spring force, not the piston pushed to the limit position, the plunger will force the sliding fork driven piston 2 pressure to limit position, while on the set of piston 1,2 3 moves to the left, piston 1 to close the inlet and the grease is sucked driven piston 1 moves to the left , when piston 2 ports open, the piston movement and rod 3 will stop, piston 1 continue to the left, the grease from the oil outlet pressure, piston 1,2 contact sliding fork movement to limit position to complete half of the cycle, so the cycle to cycle, two sets of piston alternately grease from after filtering by the filter on the connecting flange of the pump means, the oil outlet pressure is sent out, the pressure out of the grease is sent to the system for use.

How to use DRB /Z-P 40Mpa/5800psi High pressure Lubrication Portable Grease Pump:

1. The series of 40Mpa/5800psi High pressure Lubrication Portable Grease Pump should be installed in a suitable environment, low dust, easy adjustment, inspection, maintenance, and removable and washable and easy to fill grease.

2. The series lubrication pump should be as disposed in the center position of the system and shorten the length of the system piping, to maintain a minimum pressure drop, so that the pump can generate a pressure sufficient to overcome the back pressure of the lubricating points.

3. The set pressure of the pump regulator can be within the range of 0 ~ 40bar arbitrarily adjusted when in use , is not allowed to exceed the nominal pressure of the pump ( 40bar) .

4. Pump out the oil port at the filter filters should be cleaned regularly to prevent clogging.

2. The series lubrication pump should be as disposed in the center position of the system and shorten the length of the system piping, to maintain a minimum pressure drop, so that the pump can generate a pressure sufficient to overcome the back pressure of the lubricating points.

3. The set pressure of the pump regulator can be within the range of 0 ~ 40bar arbitrarily adjusted when in use , is not allowed to exceed the nominal pressure of the pump ( 40bar) .

4. Pump out the oil port at the filter filters should be cleaned regularly to prevent clogging.

5. Failure due to a series of certain reasons , the pressure reaches about 500bar, the fuse that rupture, and to identify the reasons for exclusion before inserting a new piece of insurance.

6. It must use the DJB-H1.6 electric grease filling pump to replenish lubricant grease storage receptacles grease filling port added.

7. The grease storage capacity indicator only applies to the grease, the use of medium for lubricants must swap into a float - capacity indicator.

8. Electric reducer early months must be from the vent plug hole 3# add the right amount of molybdenum disulfide grease, every four months, supplemented at a later time.

9. The series of electric lubrication pump for indoor installation, protective measures must be taken to use the outdoor or harsh environment applications.

6. It must use the DJB-H1.6 electric grease filling pump to replenish lubricant grease storage receptacles grease filling port added.

7. The grease storage capacity indicator only applies to the grease, the use of medium for lubricants must swap into a float - capacity indicator.

8. Electric reducer early months must be from the vent plug hole 3# add the right amount of molybdenum disulfide grease, every four months, supplemented at a later time.

9. The series of electric lubrication pump for indoor installation, protective measures must be taken to use the outdoor or harsh environment applications.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

High Pressure Pump

High Pressure Water Pump

Grease Pump

Air Grease Pump

Air Operated Grease Pump

Pneumatic Grease Pump

More>>

.jpg)

.jpg)