|

Egmec Industry Co., Ltd.

|

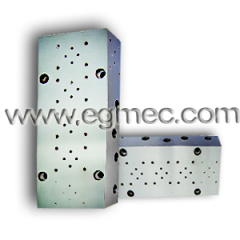

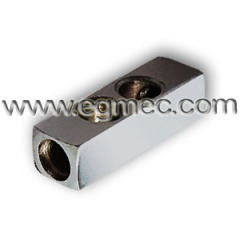

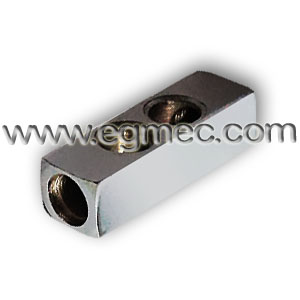

Custom Header Bar Manifolds

| Payment Terms: | T/T,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Special designed different dimensions of holes position

2. Surface polishing before chromed plated

3. All burrs are removed

Custom header hydraulic manifolds bar is used for high pressure systems, when the pressure into the bearing load zone through the lubrication manifold bar, to ensure the liquid lubrication conditions, thus avoiding the formation of hydrodynamic oil film leaving the metal friction surface (journal surface and the velocity change can not start or braking process bearing surface) direct contact with the friction and wear. Bearing Vice full-speed stable operation, the static pressure fuel supply system to stop, and with the formation of hydrodynamic oil film hydrodynamic lubrication oil, liquid lubrication conditions remain live journal bearing.

Custom Header Hydraulic Bar Manifolds

Custom Header Hydraulic Bar Manifolds

This method, in theory, bearing vice start, running, braking, reversing the whole process completely avoid the semi-liquid and boundary lubrication, a liquid lubrication. Therefore, the friction coefficient is very low, as long as to overcome the frictional resistance between the liquid internal molecular lubricant viscosity on the line. In addition, the friction surface is completely hydrostatic oil film and hydrodynamic film separated, therefore, if the situation is normal, almost no wear and tear, thereby greatly extend the working life of the bearing, saving the consumption of kinetic energy.

The manufacture processing of custom bar manifold:

In-house CAD/CAM according to drawings or samples

Outside processing for shape

Production of cut-off operations and plating to keep the materials parallel to get the cube

Precision machining to produce as the models designs

Production of CNC turning and milling reaching the threads precision

Secondary operations

Center less and thread grinding

Heat treatment if required as various working conditions

Broaching for the holes with modeled in order to keep the good dimensions

Threading

Burrs movement and tested with high pressure for materials stress

Ultrasonic clearance

Surface treatment: polishing before chrome plated and black galvanization

Packing before delivery

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)

.jpg)