|

Egmec Industry Co., Ltd.

|

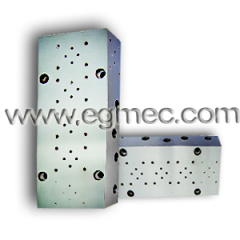

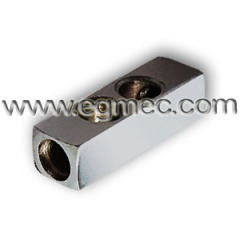

Grease Custom Hydraulic Manifold

| Payment Terms: | T/T,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. First grade aluminum materials for working pressure of 230bar

2. Aluminum oxidation surface treatment

The aluminum lubrication grease custom hydraulic manifold is the lubricant to the working of mechanical parts , is the friction deputy commissioner overloaded (or high contact stress ), high-speed , high temperature conditions, the additives in lubricants and metal friction surface reacts to generate a layer of chemical reaction film, will be two friction surfaces separated , and play a lower coefficient of friction, slowing the wear and tear ( or change the severe wear of metal surfaces in direct contact ), the role of lubrication .

Aluminum Lubrication Grease Custom Hydraulic Manifold

The processing of production manifolds:

In-house CAD/CAM according to drawings or samples

Outside processing for shape

Production of cut-off operations and plating to keep the materials parallel to get the cube

Precision machining to produce as the models designs

Production of CNC turning and milling reaching the threads precision

Secondary operations

Center less and thread grinding

Heat treatment if required as various working conditions

Broaching for the holes with modeled in order to keep the good dimensions

Threading

Burrs movement and tested with high pressure for materials stress

Ultrasonic clearance

Surface treatment like Aluminum Oxidation

Packing before delivery

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Hydraulic Valve Manifold

Hydraulic Steel Manifold

Manifold

Grease Gun

Grease Nipple

Grease Pump

More>>

.jpg)

.jpg)