|

Egmec Industry Co., Ltd.

|

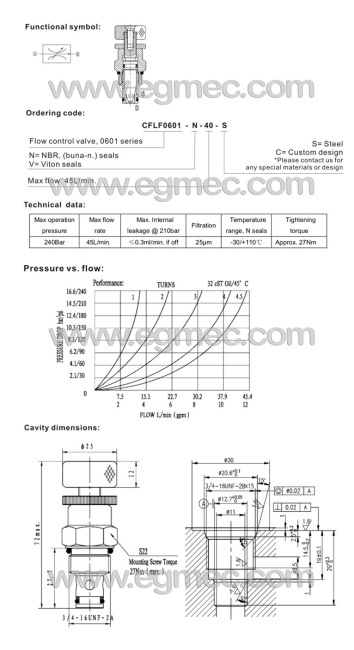

3/4 -16UNF Threaded Cartridge Type Flow Control Valves

| Price: | 11.0~13.5 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Sensitive adjusting flow rate control

2. Max. flow rate reaching 45L/min.

3. Any customized models are acceptable

The series cartridge type manually operated hydraulic adjustment flow control valve of CFLF0601 structure and shape of the valve is no difference, but they open and close parts of the shape is different.

The cartridge type manually operated hydraulic adjustment flow control valve has the following characteristics:

The cartridge type manually operated hydraulic adjustment flow control valve installation and maintenance should note the following:

The technical information of cartridge type manually operated hydraulic adjustment flow control valves :

The flow control cartridge valve opening and closing pieces are mostly cone streamlined, it changes the channel cross-sectional area through which to regulate flow and pressure. Throttle valve for the pressure drop under conditions of great pressure to reduce media use.

The cartridge type manually operated hydraulic adjustment flow control valve has the following characteristics:

1. Relatively simple structure, ease of manufacturing and maintenance costs low.

2. The regulation accuracy is not high, can not be adjusted to use.

3. The sealing surface erosion prone, can not be cut off the media used.

4. The sealing is good.

Throttle by channel can be divided into two kinds of straight-and angle; by opening and closing parts of the shape points, are needle-shaped, groove-shaped and window-shaped three.

The cartridge type manually operated hydraulic adjustment flow control valve installation and maintenance should note the following:

1. Often need to operate the valve, so it should be installed in easy-to-side operating position.

2. The installation media to pay attention to the direction of the arrow with the body of the standard is consistent.

The technical information of cartridge type manually operated hydraulic adjustment flow control valves :

Max. operating pressure: 350 bar

Rated flow capacity: 76 L/MIN

Internal leakage: ≤80ml/min

Recommended filtration: 25 MICRON

Hydraulic fluids: Mineral Oil, Viscosity 10 - 400 cST

Temperature range: -30° C to +110° C

Note: For extension of the service life, It is better to use the condition where is no gas or dust in ambient which can corrupt metal or destroy nonconductor

Please contact us for any special products.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Threaded Valves

Gas Flow Valves

Water Flow Valves

Flow Control Valve

Flow And Control Valve

Valves

More>>