|

Egmec Industry Co., Ltd.

|

Lincoln Industrial Lubrication Distributors

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Max operation pressure reaching to 200bar

2. With indicators for checking working status

3. Direct grease supplied by pushing piston

Brief introduction:

Lincoln industrial lubrication distributor series are suitable for nominal pressure 200bar dual line lubrication system as a device for metering grease, its grease supply in two turn of the supply pipe under pressure, driven by the grease pressure pistons directly to grease. complete allocation of grease to lubrication points and quantitative features. Lincoln industrial lubrication distributor series are one outlet ports on the bottom, divider forward and backward movement of the piston is grease from the same grease exit, every time the system work. the grease mouth grease one at a time.

Lubrication distributors of the series can be viewed from the indicators direct lever action dispenser may also be adjusted by adjusting the screw in easily under various lubrication grease to grease.

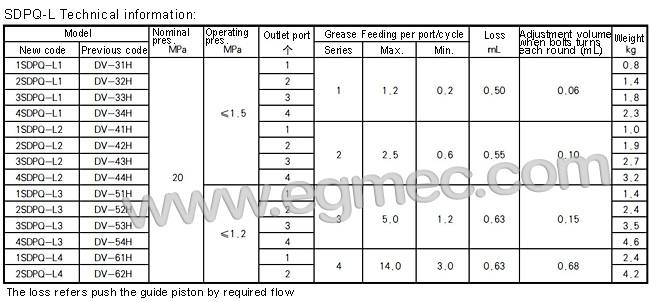

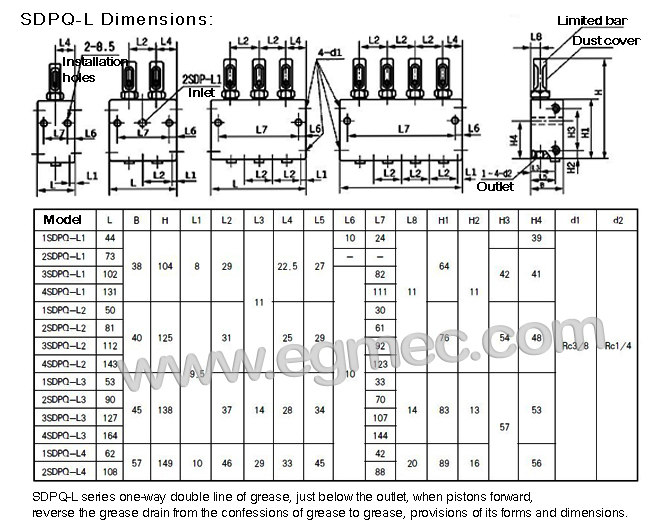

Lincoln industrial lubrication distributor of SDPQ-L series information:

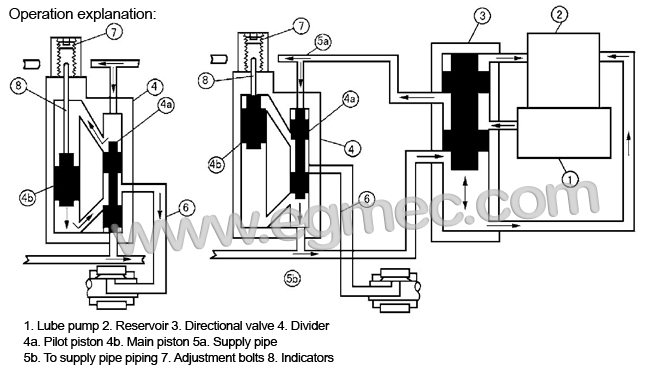

Double divider has two inlet and tubing connections with 5a. 5b, respectively. when a lubrication pump for grease. an alternative open to the grease container. From the pump pressure to be brought to grease, fuel supply line 4 5a to the dispenser into 4A upper pilot piston pressure. the pilot piston 4A under pressure. bottom for unloading fuel line 5B connectivity at this point.

As the pilot piston 4A down, so that the main cavity on cavity on the piston 4B and pilot piston connected. under the main piston cavity and outlet connection. feeding of lubricant into the main cavity on the piston. promote the piston moves down. its inferior lubricant tubing 6 NIP to the lubrication point. complete the first cycle of the oil action.

Switch to the fuel supply line 5B grease supply begins the second cycle of the oil action. distributor piston reversed the previous action in the same order, distributor per port to port by a primary 4B of the diameter and stroke of the piston to determine, by adjusting the adjusting screw 7, changing a primary 4B stroke of the piston can be realized under the oil amount adjustment.

How to use lubrication distributors of SDPQ-L series:

1. It must be used under the provisions of the environmental requirements of media.

2. Distributor of two inlet and two for tubing connection and is connected on both sides, one side of the screw on the filler opening when not in use should be blocked. Unused ports should also close screw plug (SDPQ series).

3. In dusty, humid, appalling conditions in use, should be equipped with shielSD.

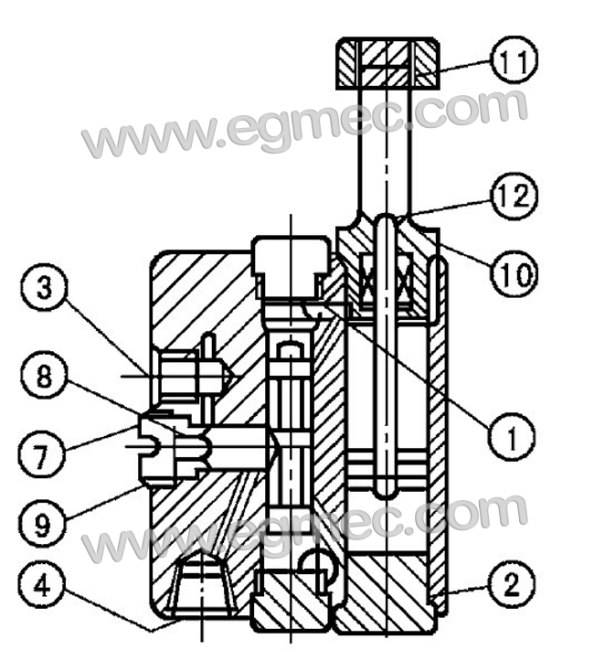

4. To the adjustment of the oil quantity. Rotary limit switch (10) on the adjustment screw (11) according to the actual neeSD of lubrication points at the maximum and minimum amount of oil in the context of adjustment to the amount of oil. Adjust the indicating bar (12) with retract, finished, tighten the locking screws.

5. To the port if the number is odd. You should plug (8) screw out plug in to the oil port (3). The oil supply port (3) and (4) connectivity. Both forward and reverse movement of the piston from the oil supply port (4) out of the oil. Priority

6. Double dispenser in the system using the parallel installation method, for tubing and distributor joins to the left or right can be; second-line method, maximum number of in-line is not allowed more than three, In particular occasions and the combination installation.

7. And Distributor contact surfaces should be smooth and tighten mounting bolts should not be too tight, so as not to influence the normal operation.

8. Distributor piston two-screw for no reason not to remove. Such as leaks should be tightened or replaced with new gaskets.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Lubrication

Lubrication System

Oil Lubrication

Lubrication Bearing

Lubrication Oil Filter

Lubrication Oil Purifier

More>>

.jpg)

.jpg)