|

Egmec Industry Co., Ltd.

|

Lubrication Greasing/ Oil Injection Pump

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Without reservoir equipped

2. Medium for industrial grease or oil

3. Large grease feeding to 400L/h

Brief introduction:

The 400Ml/Min. 1.5Kw Motor Grease Injection Pumps Of DJB Series are mainly used to grease lubrication system, supplemented grease to the reservoir of grease lubrication device. The pump without of tak -type 200L drums placed directly on a separate operation, the electronic control device is connected to electric lubrication pump system can achieve automatic grease filling. It is equipped with the interior piston displacement pump, with smooth running, high output pressure characteristics.The pump is mounted by a vertically motor drives the worm gear by the worm rotating worm end face is provided with an eccentric shaft, through a crank rod to drive the plunger down reciprocating motion provided by the role of the check valve within the piston interior and the tube cap, the completed suction process of the oil pressure by output oil hose out transport.

Ordering code:

DJB – V 400

DJB= Grease Injection Electric Pump

V= Operation pressure with 31.5bar

400= Grease feeding: 400L/h

How to use the 400Ml/Min. 1.5Kw Motor Grease Injection Pumps Of DJB Series:

Technical data:

Model | Pressure (bar) | Grease feeding (mL/min) | Piston pump | Motor | Gear reducer | |||

Speed (r/min) | Ratio | Model | Speed (r/min) | Power (kW) | ||||

DJB-V400 | 3.15 | 400 | 59 | 1:23.5 | Y90L-4 | 1400 | 1.5 | N220 |

Note: The use of media the cone penetration 220 (25 ° C , 150g ) 1/10mm grease and the viscosity grade lubricants greater than N68 .

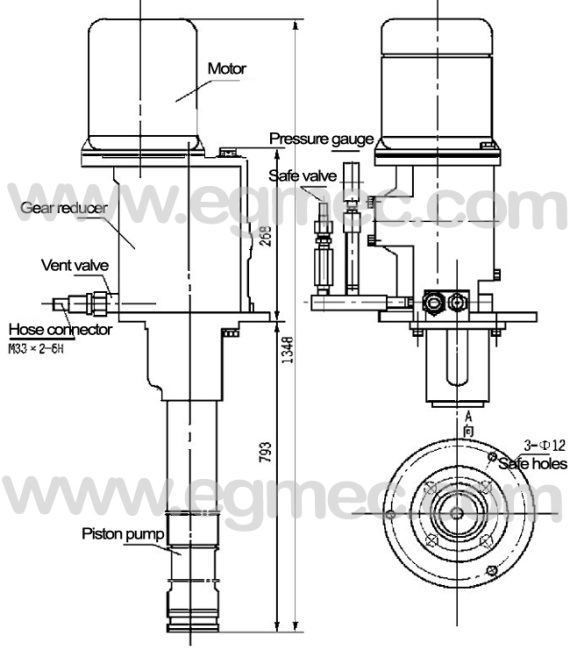

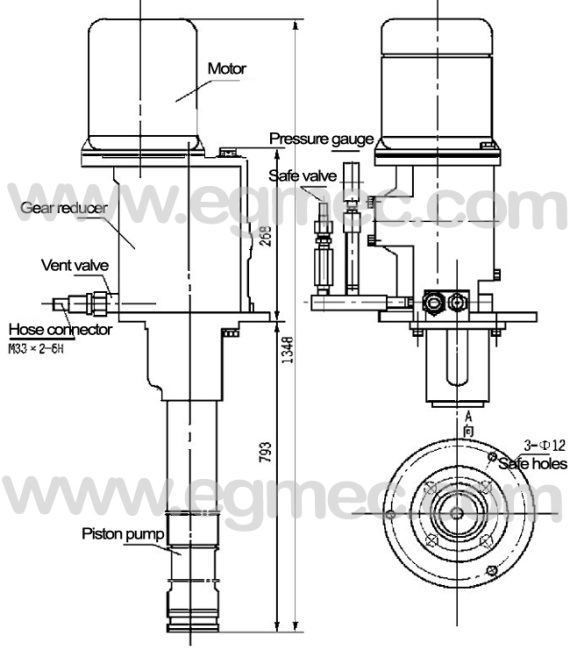

400Ml/Min. 1.5Kw Motor Grease Injection Pumps Of DJB Series Outline Dimensions:

How to use the 400Ml/Min. 1.5Kw Motor Grease Injection Pumps Of DJB Series:

1.Connection the wires as per the name plated indicated.

2.The first use of grease must be clean, uniform texture, in a specified grade range.

3.The gear box should be filled with lubrication oil (N220) to provide oil surface before using the pump at the first time.

4.The vent valve should be opened when the pump starting at the first time, and close it after the pump operation normally.

5.It is not allowed if the reservoir without grease, while the motor running no load.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Oil Lubrication

Lubrication Oil Filter

Lubrication Oil Purifier

Lubrication

Injection Pump

Fuel Injection Pump

More>>

.jpg)

.jpg)