|

Egmec Industry Co., Ltd.

|

Manual Operated Lubrication Pump

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Grease lubrication with hand operation

2. Easy installed directly on the machine or on the wall plate

3. Small size for replacement

Brief introduction:

KMPS Series single 210bar/3045PSI KMPS Manual Operated Lubrication Pump is a manual handle small discharge grease lubrication pump can be installed directly on the machine on the wall plate or rack, directly connected to form a single-wire manual centralized lubrication system with single-line distributor. The pump is small devices suitable for the lubrication frequency is low (usually oil drain intervals for more than four hours ), pipes (DN15) not more than 50 meters in length, lubrication points not more than 100 points, as a single-line centralized lubrication grease supply delivery device.

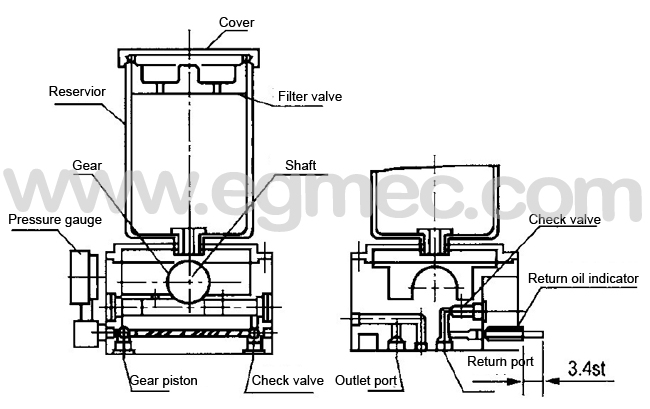

The single 210bar/3045PSI KMPS Manual Operated Lubrication Pump operated by an artificial swing handle, driven via a gear rack piston reciprocates outwardly fueling, when the piston is in the illustrated limit position , the grease is sucked through the suction port and is filled in the right chamber of the piston, when the piston toward the oil reaches the right moves, grease is sucked in the role of hydraulic top opening pressure of the check valve to the outlet is discharged outside, the main distributor of metering ports when the system is returned to the oil return indicator 3.2mL when the indicator rod fully extended, all lubrication points demonstrate that the system has the required quantity of lubricant, stop operating handle and indicator rod inwards into the preparation for the next cycle, the grease by single indicator back to the valve in the storage tank.

Ordering code:

KMPS – 2 3 R

KMPS= Manual Lubrication Pump

2= Operation pressure: 221O: 100bar

22 / 23 / 26 : 210bar

3= Reservoir volume: 3: 3L

R= With R: For lubrication oil medium; Omit: For lubrication grease

Technical data:

Model | Pressure rate (bar) | Oil feeding (mL/ Cycle) | Reservoir (L) | Weight (kg) | Medium |

KMPS-22 | 210 | 4.5 | 2 | 16 | Grease NLGO0#-1# |

KMPS-23 | 3 | 20 | |||

KMPS-26 | 6 | 23 | |||

KMPS-22R | 100 | 4.5 | 2 | 16 | Oil |

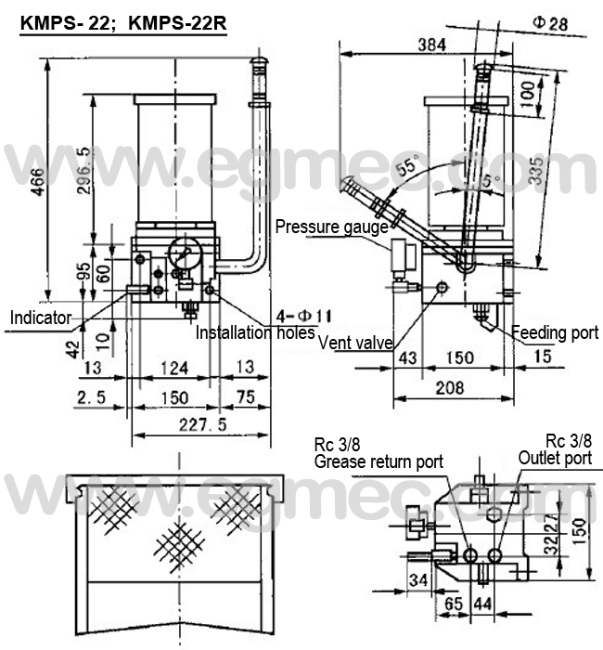

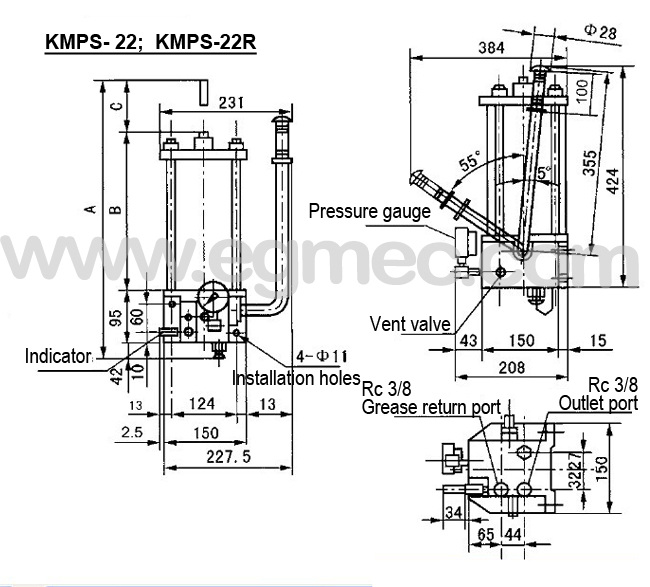

KMPS Series single 210bar/3045PSI KMPS Manual Operated Lubrication Pump dimensions:

How to use the KMPS Series 210bar/3045PSI KMPS Manual Operated Lubrication Pump:

1. Pushing the grease propulsion return indicator lever.

2. Swing the handle back and forth movement of the fluctuation of the pressure gauge pointer proof system distributor during the action of the oil.

3. Return the oil indicator rod fully extended proof system distributor has completed a cycle oil lubrication.

4. Back to the oil indicator indicating rod advance, to prepare for the next cycle.

2. Swing the handle back and forth movement of the fluctuation of the pressure gauge pointer proof system distributor during the action of the oil.

3. Return the oil indicator rod fully extended proof system distributor has completed a cycle oil lubrication.

4. Back to the oil indicator indicating rod advance, to prepare for the next cycle.

5. The 210bar/3045PSI KMPS Manual Operated Lubrication Pump should be mounted vertically above the pump and the space should be left around the indicator bar lift and the grease filling operation. Required in outdoor or harsh environment applications installed, the pump should be placed in a protective cover.

6. No grease oil in the tank allowed manipulation of the handle to the next oil level should catch up on grease .

7. Grease filling to the oil reservoir must use a manual or electric grease filling pump from grease filling feeding port.

8. The safety valve has been raised to the nominal pressure, not allowed to be adjusted.

9. The pump back to the oil indicator operator through observation indicator piston indicator rod movement stroke, knowing the condition of the grease supply of the lubrication system. Use, first calculate the lubrication of parts required to grease, configuration dispenser and an oil outlet with 210bar/3045PSI KMPS Manual Operated Lubrication Pump grease return port situated on the main distributor turns grease return to the instructions devices, such as the return of the oil accumulated 3.28mL, the indicator piston the indication rod fully extended, all lubrication points are needed to complete one cycle to the oil, should stop the grease and the grease return indicator.

Common Troubleshooting of KMPS Series single 210bar/3045PSI KMPS Manual Operated Lubrication Pump:

Breakdown | Reason | Elimination method |

Pump output pressure does not rise up | 1. Pressure gauge damage 2.Oil tank and piping into the air 3. Safety valve low pressure overflow 4. Long time operation, The plunger and sets excessive wear 5. Check valve failure | 1. Replacement pressure gauge 2. Open vent valve exhaust 3. Adjust the safety valve relief pressure 4. Replacement parts 5. Clean the check valve and replace the spring |

Sharp rise of the output pressure from the pump | 1.Pipe lines clogged 2.Main distributor malfunction | 1. Check pine tubing 2. Observation distributor action |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Manual Operated Valve

Manual Pump

Air Operated Grease Pump

Air Operated Diaphragm Pump

Air Operated Oil Pump

Hand Operated Pump

More>>

.jpg)

.jpg)