|

Egmec Industry Co., Ltd.

|

Multi-point Grease Lubrication Pump

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Multi-point lubrication to 18 ports

2. Reliable motor supplying power

3. Stable operation characteristics

Brief introduction:

Using the medium for the cone penetration of not less than 265 (25 ℃, 150g) 1/10mm the grease (NLGI0 # ~ 2 #). Working ambient temperature 0 ~ 40 ℃.

Lubrication Pump Equipment: DDB-10, DDB-18, DDB-36.

How to use Multi-point Grease Lubrication Pump DDB18 0.75Kw Motor Power 100bar/1450psi Working Pressure:

1. The series of Multi-point Grease Lubrication Pump DDB18 0.75Kw Motor Power 100bar/1450psi Working Pressure should be installed right at ambient temperature, dust a small, easy to fill fat, adjustment, inspection, maintenance and so convenient occasions.

2. Multi-point grease lubrication pump ddb18 0.75kw motor power 100bar/1450psi working pressure using the box before the start of a slowdown by adding HL-20 gear oil to the oil standard provisions of liquid.

3. To the Lubrication Pump oil storage device must be used within the lipid supplement SJB-D60 hand-pumps or DJB-200 electric fuel pumps fuel from the oil storage device port to join, pay attention to the inside of an oil storage grease are forbidden to start the motor without operation.

4. According to storage barrels to spin the walls of the spiral to the licensing requirements for electrical wiring, shall not be reversed.

5. Filling the mouth of filter accuracy of not less than 0.2mm, should be regularly cleaned.

6. Dry pumps should always be kept clean, non-fat uncovery fill dirt into the pump body so as not to affect the normal work.

Multi-point Grease Lubrication Pump DDB18 0.75Kw Motor Power 100bar/1450psi Working Pressure suitable for the lubrication frequency is very low, lubrication points not more than 50 points, the nominal pressure 10MPa multi line dry oil lubrication system.

Multi-point Grease Lubrication Pump DDB18 0.75Kw Motor Power 100bar/1450psi Working Pressure

Multi-point Grease Lubrication Pump DDB18 0.75Kw Motor Power 100bar/1450psi Working Pressure

Directly or via the singlet -piece to the oil supply device of grease all lubrication points, especially applicable to the crusher, forging machine, terminal line hanging, printing presses and other small, stand - alone device.

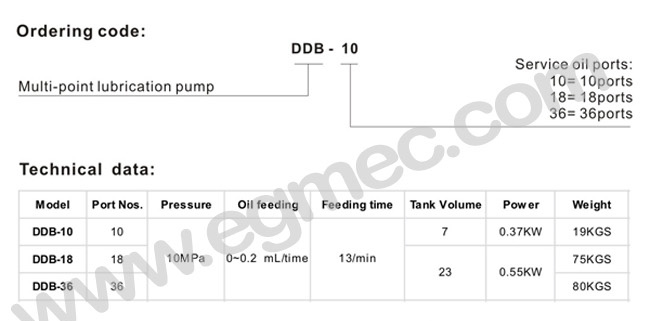

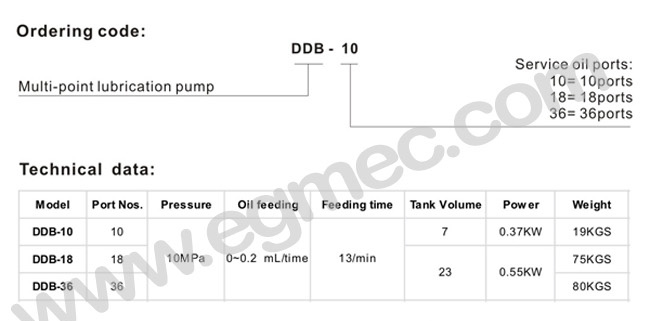

The technical information of Multi-point Grease Lubrication Pump DDB18 0.75Kw Motor Power 100bar/1450psi Working Pressure:Ordering code | Pressure (MPa) | Displacement, per day (ml/time) | Oil supply (/min) | Tank volume (L) | Motor power (kW) | Weight (kg) | |

DDB-10 | 10 | 10 | 0-0.2 | 13 times | 7 | 0.37 | 19 |

DDB-18 | 18 | 23 | 0.55 | 75 | |||

DDB-36 | 36 | 80 | |||||

Using the medium for the cone penetration of not less than 265 (25 ℃, 150g) 1/10mm the grease (NLGI0 # ~ 2 #). Working ambient temperature 0 ~ 40 ℃.

Lubrication Pump Equipment: DDB-10, DDB-18, DDB-36.

How to use Multi-point Grease Lubrication Pump DDB18 0.75Kw Motor Power 100bar/1450psi Working Pressure:

1. The series of Multi-point Grease Lubrication Pump DDB18 0.75Kw Motor Power 100bar/1450psi Working Pressure should be installed right at ambient temperature, dust a small, easy to fill fat, adjustment, inspection, maintenance and so convenient occasions.

2. Multi-point grease lubrication pump ddb18 0.75kw motor power 100bar/1450psi working pressure using the box before the start of a slowdown by adding HL-20 gear oil to the oil standard provisions of liquid.

3. To the Lubrication Pump oil storage device must be used within the lipid supplement SJB-D60 hand-pumps or DJB-200 electric fuel pumps fuel from the oil storage device port to join, pay attention to the inside of an oil storage grease are forbidden to start the motor without operation.

4. According to storage barrels to spin the walls of the spiral to the licensing requirements for electrical wiring, shall not be reversed.

5. Filling the mouth of filter accuracy of not less than 0.2mm, should be regularly cleaned.

6. Dry pumps should always be kept clean, non-fat uncovery fill dirt into the pump body so as not to affect the normal work.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Multi Point

Grease Pump

Air Grease Pump

Air Operated Grease Pump

Pneumatic Grease Pump

Hand Operated Grease Pump

More>>

.jpg)

.jpg)