You are here: home > Lubrication Equipment > Double Line Lubrication System Introduce

Product (427)

- Lubrication Distributors (28)

- Lubrication Equipment (26)

- Hydraulic Manifolds (47)

- Hydraulic Systems (16)

- Hydraulic Motors (9)

- Hydraulic Pumps (27)

- Rexroth Spool Valves (3)

- Rexroth Solenoid Valves (3)

- Rexroth Directional Valves (3)

- Solenoid Operated Directional Valve (3)

- Rexroth Solenoid Directional Valves (4)

- Hydraulic Directional Control Valve (3)

- Rexroth Directional Control Valves (3)

- Manual Directional Control Valves (3)

- Rexroth DBDS Pressure Relief Valve (3)

- DBDS Pressure Relief Valves (2)

- Rexroth DBD Valves (3)

- Rexroth Pilot Operated Pressure Relief Valves (4)

- Rexroth Pressure Relief Valves (4)

- Rexroth Relief Valves (3)

- Rexroth Flow Control Valves (6)

- Rexroth Check Valve (8)

- Yuken Directional Valves (6)

- Yuken Proportional Valves (3)

- Yuken Reducing Valves (2)

- Yuken Relief Valve (2)

- Yuken Check Valves (6)

- Vickers Directional Control Valves (2)

- Hydraulic Cartridge Valves (47)

- Hydraulic Valve Solenoids (27)

- Hydraulic Parts (24)

- Hydraulic Fittings (20)

- Valve Amplifiers (10)

- Hydraulic Pressure Sensors (17)

- Terex Parts (45)

- Others (5)

Products List (16)

Certificates (4)

News (24)

Hydraulic Manifold Blocks (7)

Hydraulic Control Valves (1)

Hydraulic Cartridge Valves (6)

Industrial Hydraulic Pumps (22)

Electromagnet Solenoids (18)

Lubrication Equipment (28)

Electronic Amplifiers (8)

Hydraulic Power Systems (10)

Hydraulic Hose Fittings (7)

Transporation Information (1)

Credit Report

Products Index

Company Info

Egmec Industry Co., Ltd. [China (Mainland)]

Business Type:Manufacturer, Trading Company, Agent

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

Lubrication Equipment

Double Line Lubrication System Introduce

Double Line Lubrication System Introduce

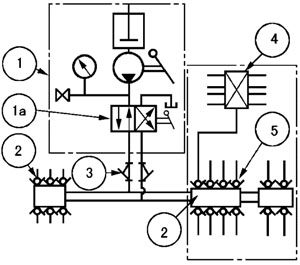

Manual terminal systems:

By the position of valve 1a of the lubricant lubrication pump 1. output by two oil executives for the delivery of a one and one oil storage device to open. Lane divider 2.All the action is completed, a sharp rise in oil pressure.

Available in advance to confirm whether the oil pressure to determine the value of the system to the oil has been completed and run again to the oil system, the valve 1a in the opposite position, then oil pressure delivery charge and open exchange.

The characteristics of the system are simple, low cost. For a long time interval to the oil, lubrication points less occasions. Also meet with other systems, some special parts of the lubrication.

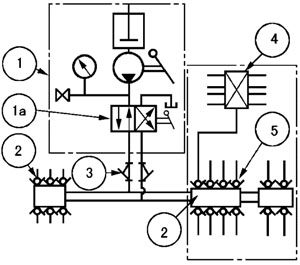

Electric terminal systems:

The cabinet 5.directive within the time set by the relay to the system in accordance with the oil interval automatic action, according to "extend to the oil," said the work exceptions to the oil, the other with "oil storage is empty," "Overload operation "and other warning signals. Instruction time a relay system to the oil according to the actual work time plus 2 to 5 minutes to adjust. Head end of the oil pressure control valve with pressure switch or pressure switch valve or two valves (one per line with) 4, when the end of the pressure reaches the set value, send signals to the control cabinet, valve 1a commutation, lubrication pump 1 time to stop the oil system is completed. After a set time interval, the system working again, another main pipeline from the oil.

System design is usually the time by 5 minutes for the oil (up to 8 minutes or less) design, the pressure switch / pressure control valve of standard setting pressure 5MPa so. Pressure switch / pressure control valve set pressure loss in charge of the largest oil supply at the end, the proposed layout of a splitter and then the back (see below double-dotted box) in order to grease the end of the update. For small systems, to facilitate the electrical wiring, pressure control can be used for the front, that is two outs in the pipeline valve pressure controller installed in parallel, at the end need to install pressure switch / pressure control valve. Second,

The characteristics of electric terminal systems

The piping costs are lower. Pressure to end the use of oil as the completion of system control parameters, the design is easy. Lubrication points for wider distribution of the occasion.

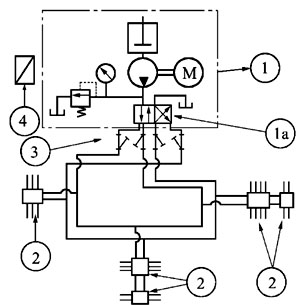

Electric ring system:

The cabinet 4. directive within the time set by the relay to the system in accordance with the oil interval automatic action, instruction time with the "extended to oil," said the work exceptions to the oil, the other with "oil storage is empty," " overload operation "and other warning signals. Instruction time a relay system to the oil according to the actual work time plus 2 to 5 minutes to adjust. Hydraulic valve switch 1a has two oil executives and controlling oil pressure head at the end of the function, when the oil pressure to the head end of the set pressure of the hydraulic valve, hydraulic valve commutation to cabinet to send signals, lubrication pump 1. stop, the system working again, another main pipeline from the oil. System design is usually the time by 5 minutes for the oil (up to 8 minutes or less) design, a standard hydraulic valve set pressure 5MPa

The characteristics of Electric ring system:

The end of the oil supply line pressure control valve for the direct, reliable action, valve installed in the lubrication pump, electrical wiring and low cost. Lubrication pump on the pressure in the adjustment, maintenance, inspection convenience. Lubrication points are concentrated for the occasion.

Pre Page:

Importance of Lubrication Equipment

Next Page:

The Importance of Lubrication Equipment

.gif)